Technology

Copenhagen Atomics is developing a thorium molten salt reactor, with the focus on low electricity price and fast installation

The first test reactors (2027) and first commercial reactors (2030) will run on 5% enriched uranium as fuel salt and thorium as blanket salt.

With high enriched Li7 for optimal neutron economy, CAs reactors will have better neutron economy than any other reactor ever designed or build.

The first reactors will not be breeder reactors, meaning that they will generate more fissile fuel than they consume. But they will have breeding ratio approaching 1 (iso breeder).

Future potential

In the long term Copenhagen Atomics wishes to make thorium breeder reactors in the thermal spectrum (slow neutrons)

These breeder reactors will use either LEU (5% enriched uranium) or TRU (transuranics from spent nuclear fuel) as kickstarter fuel

In the TRU case, Copenhagen Atomics’ reactor will become one of the most efficient “waste burners” you can build

Why thorium?

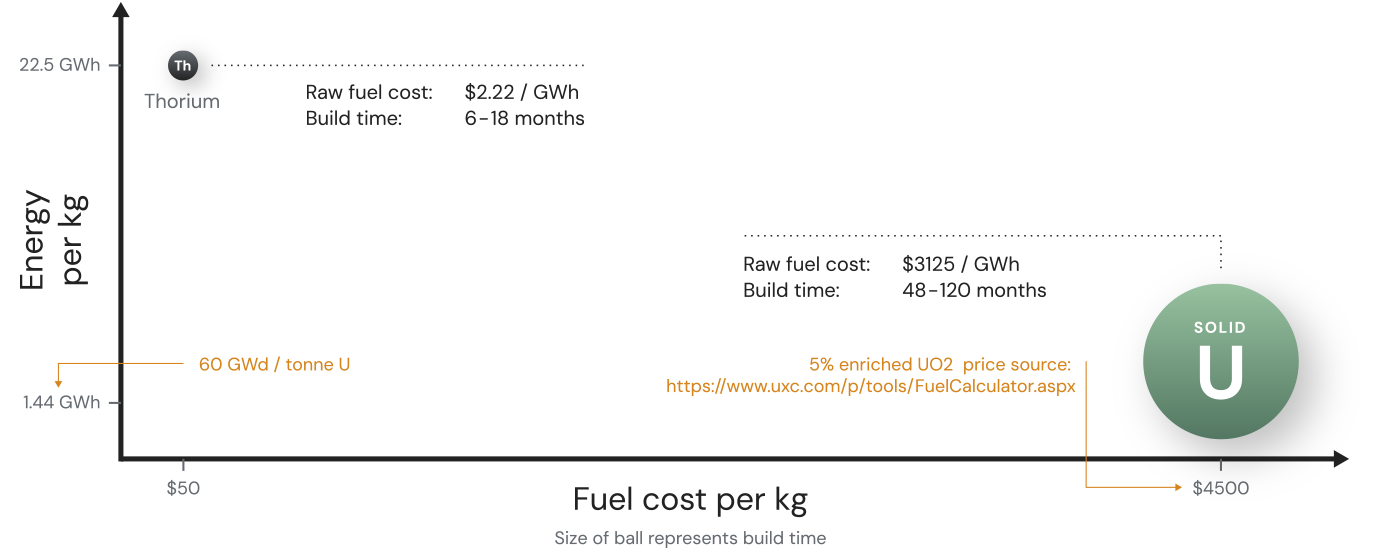

Thorium is a much better fuel than uranium with 2.22 USD/GWh raw fuel cost in the Copenhagen Atomics' thorium reactor. For most other solid fuel reactors the raw fuel cost is 1,500 - 10,000 USD/GWh of thermal energy.

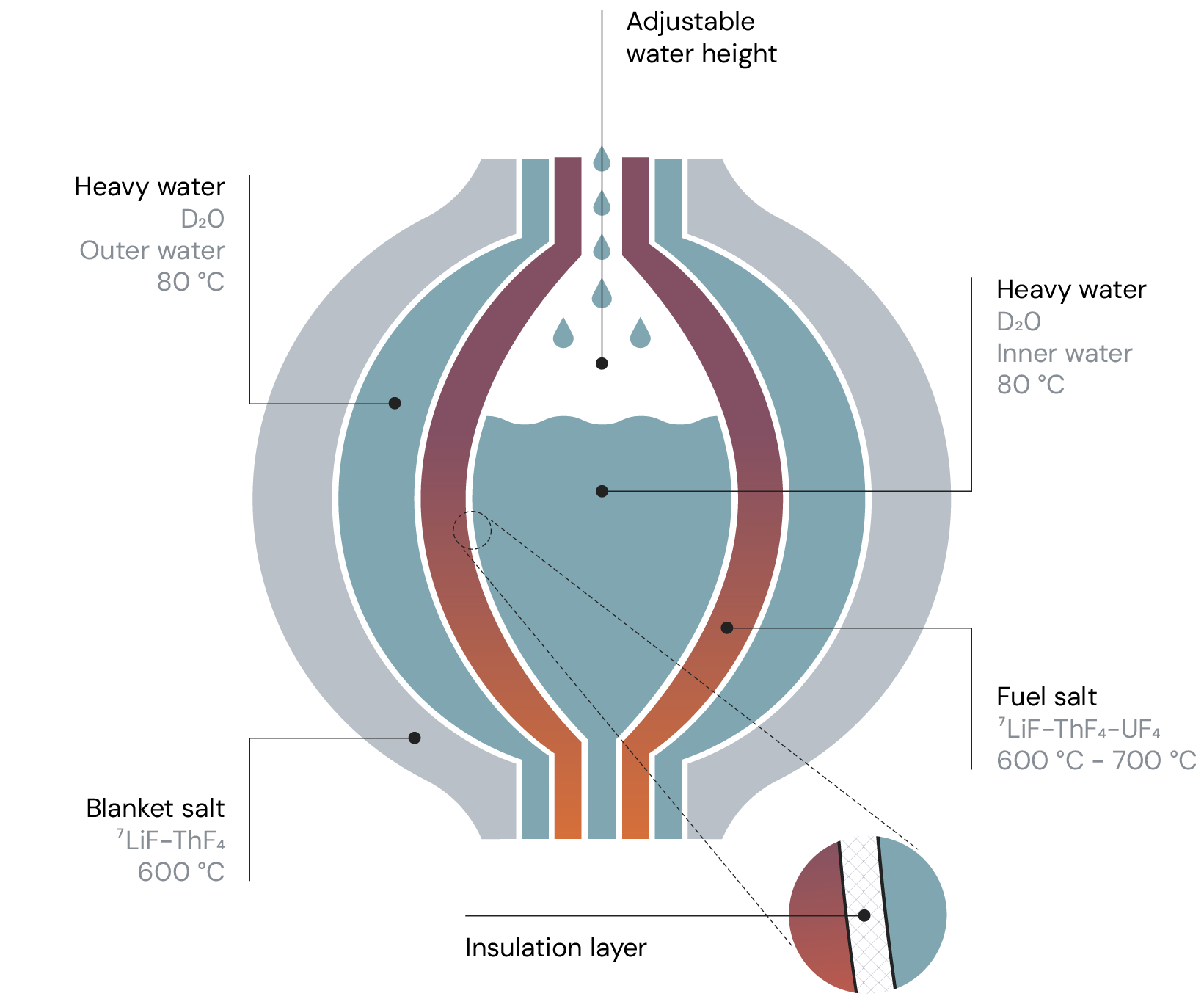

The Onion Core®

Thorium also enables the existence of the Onion Core®

Copenhagen Atomics has invented the Onion Core®, which allows us to make a compact reactor that can easily be mass-manufactured and only require small amount of materials. This is a game changer for nuclear energy.

The construction cost of the reactor and auxiliary systems is also less than traditional nuclear reactors.

Copenhagen Atomics have already built two prototype reactors (with the Onion Core®) and is on its way to build a third reactor.

Removing the complexity for decision makers. Companies fear the responsibility of operating a nuclear plant, decommissioning, and handling nuclear waste. We take care of all of that and just deliver reliable and green energy to the customer.

Co-founder

Assembly line production

Containerized molten salt reactors allows for mass manufacturing and assembly line production. No onsite reactor assembly is necessary, only installation. This enables us to bring low cost manufacturing to the nuclear industry.

Burning spent nuclear fuel

By kickstarting our reactors on long-lived "waste" left in spent fuel we're able to convert it to fission products, which only needs to be stored for 300 years while rapidly scaling global energy production without the need for uranium enrichment.

Thorium and molten salt

There’s already enough mining of thorium today, that we can get all the thorium we need to power all of current civilization for the next thousand years. However, its true potential as an energy source can only be realized when used as a molten salt.

Specifications

-

Reactor output100 MWth

-

Temperature served to customers550 °C

-

Kickstarter fuelF7LiThLEU & F7LiThPu

-

Moderatorunpressurized heavy water

-

Neutron spectrumThermal

-

Fuel cycleBurn-then-breed

Thorium the solution

Thorium is the only element that allows for a breeder reactor in thermal spectrum. This means that the power output per kg of fissile inventory can beat any other reactor.

Engineering focused approach to reactor development

Development is driven by extensive and iterative testing of components, which has already birthed several innovations

- Circulates molten salt continuously in a loop in which various materials/components can be inserted

- Flexible design allows for frequent modification to tests

- Test loops have already aided in the development, testing and verification of several reactor components

- Test data from customers is shared with Copenhagen Atomics lowering the Company’s own testing needs

Test loops are crucial in the development of molten salt reactors and allow for verification of reactor parts

FAQ

Copenhagen Atomics reactors do not extract protactinium.

Copenhagen Atomics reactors extract fission products while the reactor is running.

Copenhagen Atomics breeder reactors will not generate spent nuclear fuel, like all the other uranium reactors out there. Instead, we generate fission products as waste stream, which only need to be stored above ground for 300 years. This is regardless of which Kickstarter fuel we use (LEU or TRU).

Copenhagen Atomics will supply the fuel salt. We do not rely on 3rd party fuel suppliers. But we buy LEU, TRU and thorium from an existing supply chain. Copenhagen Atomics already has agreements for the thorium supply chain but will need to increase the capacity of all the supply chains to reach our goals.