Test salts like FLiNaK and FLiBe, fuel salts like UF4 and ThF4, and enriched lithium delivered as LiF

Copenhagen Atomics is a leading manufacturer of highly purified salts for molten salt reactors, fusion, academic and similar applications.

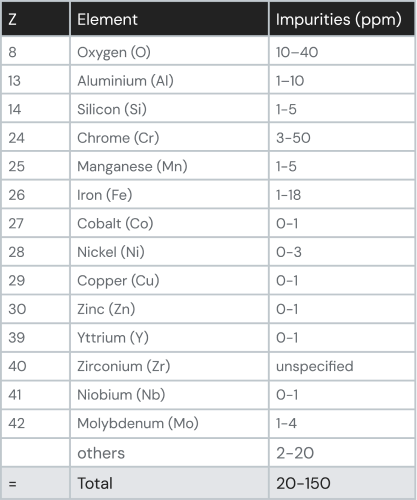

Salts are provided in purity as low as 20 ppm oxides. Using these purified salts it is possible to significantly eliminate corrosion.

We are providing a number of clean, dry, and pre-melted salts. These salts are:

Highly purified salts

FLiNaK

Fuel salts

Uranium fuel salt (UF4) and Thorium fuel salt (ThF4)

Enriched Lithium

Li-6 salt and Li-7 salt