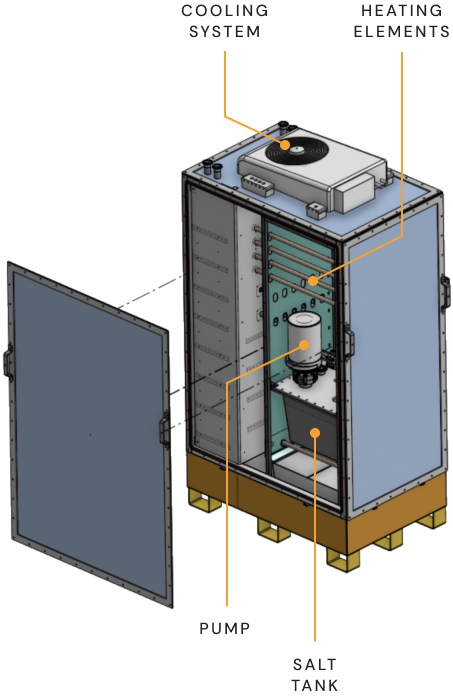

Fully autonomous operation with up to 600°C flowing molten salt

The Copenhagen Atomics pumped molten salt loop comes complete with control software, which can be operated from a mobile-phone app.

Operating conditions are logged, cloud hosted, and can be viewed online or downloaded as a .CSV file using a customer specific log-in and password.

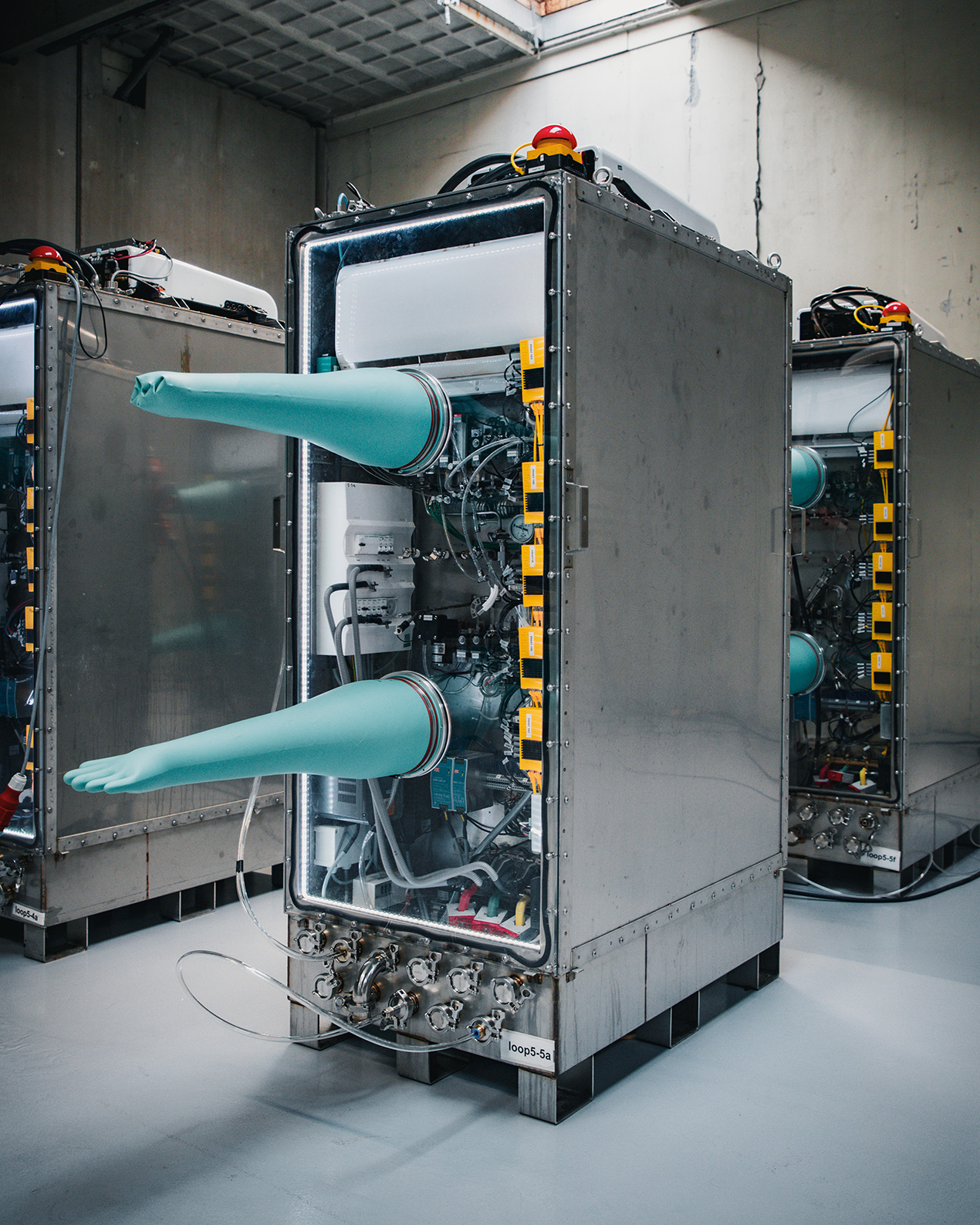

Copenhagen Atomics specialists are available for hands-on assistance during installation at the customer location.